Aerospace

Learn More

R.S. Hughes anuncia la inauguración de las modernas instalaciones de fabricación de Saunders en Houston

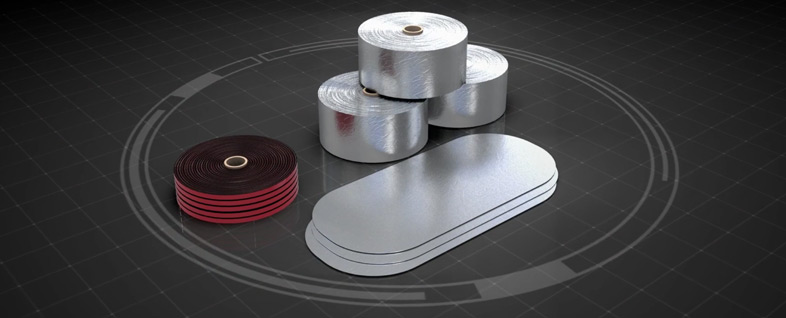

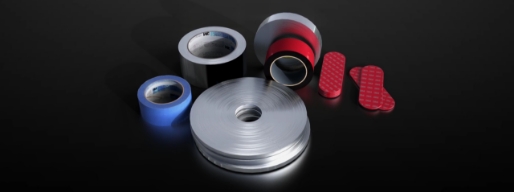

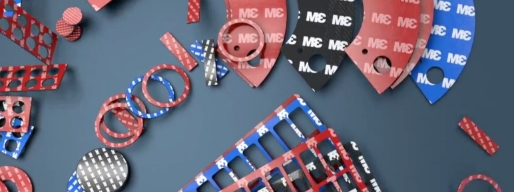

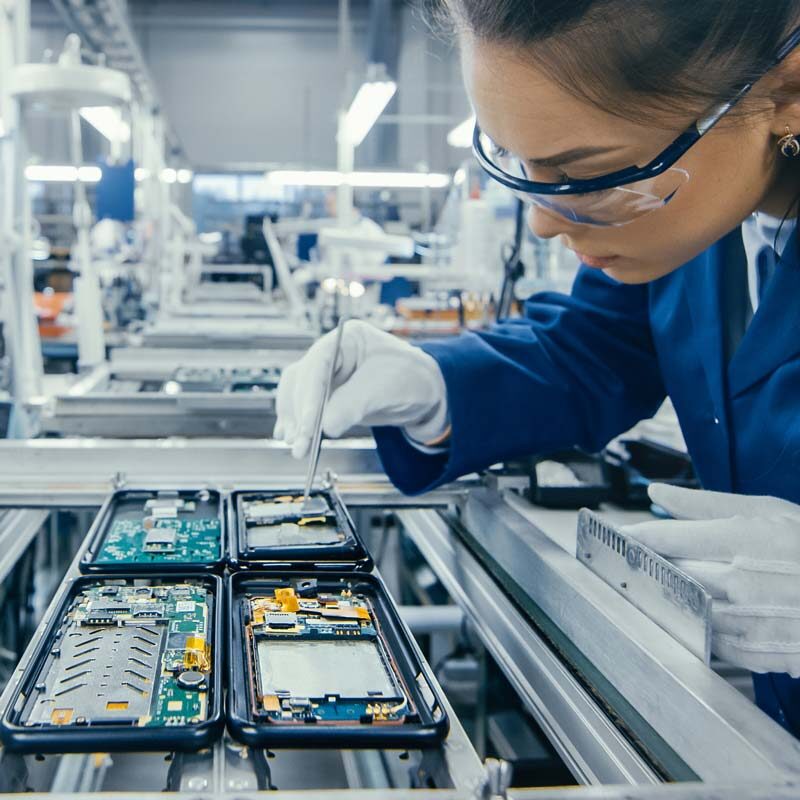

Saunders provides several converting services such as die-cutting, laminating, slitting, packaging, assembly, and other manufacturing solutions to our customers at highly competitive industry rates.

Provide us with some basic details about both you and your project. From there, we'll do the research necessary to find you the best solution that fits your needs.

Once we believe we've found the perfect solution, our team will reach out to you to get a deeper understanding of your project. We want to ensure the solution we provide is going to last, which means working hand-in-hand with you throughout the entire process.

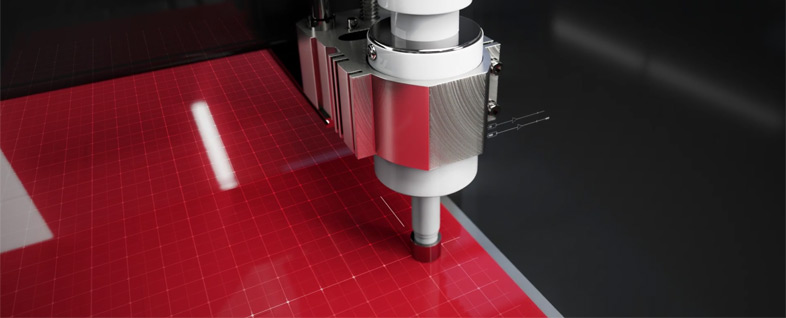

Once a design has been agreed upon, that's when we get to work. Using the highest quality of materials and state-of-the-art cutting technology, we create your custom fit solution, and ensure that it rises to the toughest of challenges.

We will work tirelessly to make sure your product is delivered on time, and at the quality you've come to expect from Saunders. We will not rest until we've provided you with the best solution available.

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Learn More

Is your company facing a product manufacturing challenge? Do you need a custom fit solution that will help improve your overall product production? Contact us today and let's start working together towards finding the perfect solution.