Custom Converted Solutions for Electronic Applications

Introduction to Custom Converted Solutions

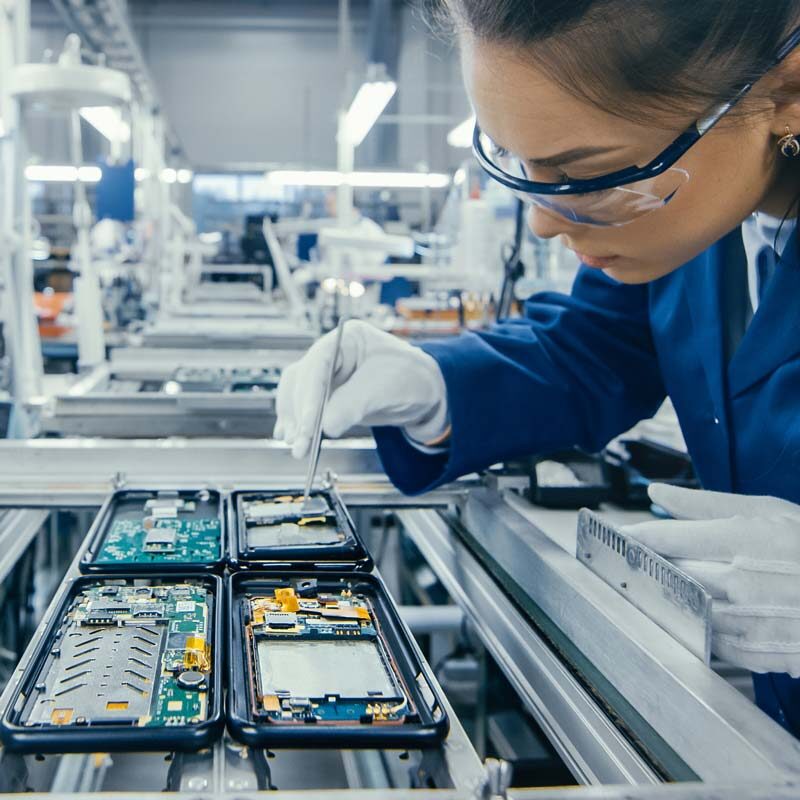

Welcome to the world of custom converted solutions for electronic applications, where innovation meets precision to cater to your unique needs. In a fast-paced technological era, flexibility and customization are key, driving the demand for tailored solutions in the electronics industry. Let’s explore how customized conversions can revolutionize the way electronic applications are designed and utilized.

The Growing Demand for Electronic Applications

The growing demand for electronic applications is undeniable in today’s fast-paced world. From smartphones to smart homes, electronic devices have become an integral part of our daily lives. As technology continues to advance, the need for more innovative and efficient electronic solutions is on the rise.

Consumers are constantly seeking products that offer convenience, connectivity, and customization. This demand has led to a surge in the development and manufacturing of new electronic applications across various industries such as medical, automotive, aerospace, transportation, electronics and more.

Manufacturing engineers are also recognizing the importance of adapting to this digital era by incorporating cutting-edge technologies into their operations. Whether it’s optimizing manufacturing processes or enhancing product qualities, electronic converted parts play a crucial role in driving business growth and staying competitive in the market.

The growing demand for electronic applications signifies a shift towards a more connected and tech-savvy society where innovation thrives.

Challenges Faced in the Electronics Industry

The electronics industry is a dynamic and fast-paced sector that constantly faces various challenges. One of the major hurdles in this industry is keeping up with rapid technological advancements. With new innovations emerging frequently, companies must stay agile to remain competitive.

Another challenge is ensuring product reliability and durability. Electronics need to withstand harsh conditions while maintaining optimal performance. This requires rigorous testing and quality control measures to meet consumer expectations.

Supply chain disruptions can also pose significant challenges for electronics manufacturers. Any delays or shortages in components can impact production schedules and result in increased costs.

Moreover, data security concerns are a growing challenge in the electronics industry. As technology becomes more interconnected, protecting sensitive information from cyber threats is crucial for both businesses and consumers alike.

Staying ahead of these challenges requires proactive strategies and continuous innovation within the electronics industry.

Benefits of Custom Converted Solutions

Custom converted solutions offer a range of benefits for electronic applications. One key advantage is the ability to tailor the product precisely to meet specific requirements. This customization ensures optimal performance and efficiency in your electronic devices.

Another benefit is cost-effectiveness. By eliminating unnecessary features and components, custom converted solutions can help reduce production costs while still delivering high-quality results. This way, you only pay for what you need.

Furthermore, customized solutions often lead to faster time-to-market as they are designed to fit seamlessly into your existing systems. This streamlined integration process saves time and resources, giving you a competitive edge in bringing new products to market swiftly.

Additionally, custom converted solutions enhance overall product reliability and durability by addressing unique challenges faced in electronic applications. With tailored designs that account for environmental factors or usage conditions, these solutions can significantly extend the lifespan of your devices.

Types of Custom Converted Solutions Available

When it comes to custom converted solutions for electronic applications, there is a wide range of options available to meet specific needs and requirements. One common type is die-cut components, which are precision-cut pieces used in various electronic devices to provide insulation, protection, or functionality.

Another popular solution is adhesive tapes and films tailored to withstand extreme temperatures, provide electromagnetic shielding, or offer secure bonding between components. These customizable tapes can enhance the performance and longevity of electronic products.

Custom gaskets and seals are essential for protecting electronics from dust, moisture, and other environmental factors. By creating bespoke gaskets using materials like silicone or rubber, manufacturers can ensure a perfect fit for their devices.

Conductive materials such as foams or films play a crucial role in managing electrical currents within electronic assemblies. These materials can be customized to optimize signal transmission and reduce electromagnetic interference in sensitive applications.

Innovative 3D printing technology has also revolutionized the production of custom parts for electronics. Companies can now create intricate designs with high precision using advanced additive manufacturing techniques.

Case Studies: Successful Implementation of Custom Converted Solutions

In the realm of electronic applications, success stories abound when it comes to implementing custom converted solutions. These case studies serve as shining examples of how tailored solutions can revolutionize industries. Take for instance a company in the automotive sector that struggled with finding a compact yet efficient power source for their new electric vehicle model.

By partnering with a provider of custom converted solutions, they were able to design and integrate a bespoke battery system that met their specific requirements. The result? A cutting-edge electric vehicle that exceeded performance expectations and set new industry standards.

Similarly, in the healthcare field, another case study showcases how custom converted solutions transformed patient monitoring devices. Through innovative engineering and customization, a medical device manufacturer was able to create wearable sensors that provided real-time data with unmatched accuracy and reliability.

These success stories underscore the importance of thinking outside the box when it comes to electronic applications. By embracing customized solutions, companies across various sectors can achieve unparalleled results and stay ahead of the competition.

Choosing the Right Provider for Your Electronic Application Needs

When it comes to choosing the right provider for your electronic application needs, it’s crucial to do thorough research and ensure you find a company that aligns with your requirements. Look for a provider with a proven track record in delivering custom converted solutions tailored to the electronics industry.

Consider factors such as expertise, experience, and the ability to offer innovative solutions that cater to your specific needs. A reliable provider will have a team of experts who can understand your challenges and provide you with customized solutions that optimize performance and efficiency.

Don’t forget to check reviews and testimonials from previous clients to gauge the quality of service provided by the company. Communication is key when selecting a provider, so make sure they are responsive, transparent, and willing to work closely with you throughout the process.

Choosing the right provider for your electronic application needs will play a significant role in achieving success in your projects.

Future Outlook and Advancements in Custom Converted Solutions

As technology continues to evolve, the future of custom converted solutions for electronic applications looks promising. Advancements in materials and manufacturing processes are paving the way for more innovative and efficient solutions.

In the coming years, we can expect to see even greater customization options tailored to specific industry needs. From improved thermal management solutions to enhanced electrical insulation capabilities, the possibilities are endless.

With a growing emphasis on sustainability and eco-friendly practices, future advancements may also focus on developing greener alternatives that reduce environmental impact without compromising performance.

Additionally, as digital transformation accelerates across industries, custom converted solutions will play a crucial role in enabling seamless integration with IoT devices and smart technologies.

The outlook for custom converted solutions is bright, with continued advancements driving innovation and shaping the future of electronic applications.

Conclusion

Custom converted solutions offer a tailored approach to meet the unique needs of electronic applications. As technology continues to advance and industries evolve, the demand for customized solutions will only grow. By overcoming challenges in the electronics industry and providing benefits such as improved efficiency, performance, and cost-effectiveness, custom converted solutions are paving the way for innovation and progress.

Choosing the right provider for your electronic application needs is crucial in ensuring successful implementation. With a focus on quality, expertise, and customer satisfaction, selecting a trusted partner can make all the difference in achieving desired results.

As we look towards the future, advancements in custom converted solutions will continue to drive improvements in various electronic applications. By staying at the forefront of innovation and adapting to changing market demands, businesses can stay competitive and thrive in an ever-evolving technological landscape.

Custom converted solutions have proven to be instrumental in addressing complexities within the electronics industry while unlocking new possibilities for growth and development. Embracing customization not only solves current challenges but also sets the stage for future success.