Each Die Cutting Method Explored – Rotary Die Cutting

Now that you understand each method’s basic mechanics, let’s dive into the advantages and disadvantages. Remember that just like any manufacturing process, the most efficient method is usually the one that best matches the project’s needs.

1. ROTARY DIE CUTTING – Recommended for high-volume cutting runs.

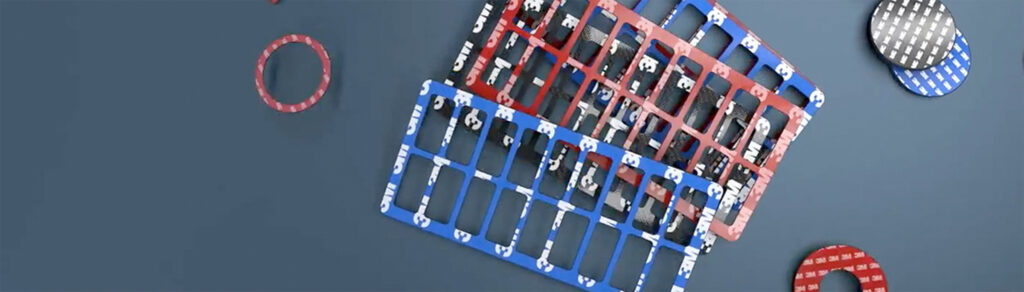

A rotary die is a cutter and roller in one, that when the material passes under it, a shape is rolled out. A rotary die cutting cylinder allows for multiple and continuous shapes to be cut quickly from material provided in roll form.

The press’s rotating cylinder blade cuts the material to exact lengths, keeping tight tolerances by using servo motors to maintain registration. Rotary dies, known for their durability, can cut rolls of material that perfectly fit on same-sized objects, which is a critical advantage for parts in the medical, military, and aerospace industries, among others.