Each Die Cutting Method Explored – FlatBed Die Cutting

Now that you understand each method’s basic mechanics, let’s dive into the advantages and disadvantages. Remember that just like any manufacturing process, the most efficient method is usually the one that best matches the project’s needs.

2. FLATBED DIE CUTTING – Simple can be very useful.

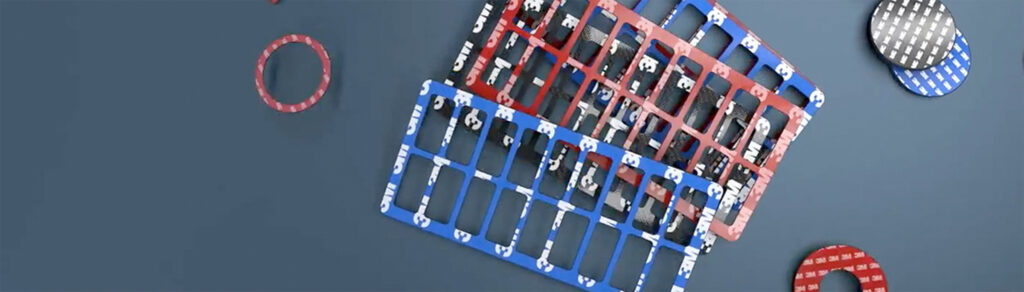

Flat bed die cutting is often seen as the most basic method of cutting a material and is the method of choice for many projects. This process involves using a flat bed machine equipped with sharp steel blades, known as dies, to cut out specific shapes from sheets of material. This results in clean and accurate cuts. Flatbed die cutting offers remarkable precision and versatility by ensuring uniformity across multiple identical pieces without any variations or deformities. This technique enables mass production and can rapidly produce large quantities in a short period.

Flatbed die cutting provides endless possibilities for customization and innovation in product design due to its ability to create complex shapes effortlessly. Moreover, this cost-effective method eliminates unnecessary waste since it optimizes material usage by carefully arranging different shapes on one sheet before cutting them out simultaneously.

Flatbed die cutting offers outstanding accuracy and versatility across a number of industries. Tools can be changed easily and quickly, making flatbed die cutting an excellent choice for low-volume projects or if a product isn’t working correctly on a rotary or laser-cutting machine.